Martinus is in a unique position within the rail industry with an extensive range of critical plant and equipment for track construction. Our plant team have in-house logistics and maintenance capabilities that allows us to retain full control of all aspects of logistics and maintenance.

LOCOMOTIVES

• Quantity – 8

• DC Class

• 1600Hp

BALLAST WAGONS

• Quantity – 40

• Gauge convertible

• Remote operation of ballast delivery

• 100T capacity per wagon

OLE manitou boom

• Quantity - 2 EWP

• Tri-Gauge

• OLE Maintenance and Construction

VAIA CAR - TLPS 2500

- This model has already been converted for use on narrow gauge railways and is in excellent operational condition.

WAGONS AND GANTRIES

- Gauge convertible

- Quantity – 42

- 26 configured as sleeper wagons to support track layering machine

- 16 configured as rail delivery train

FLASH BUTT WELDERS

- Quantity – 5EO Paton Containerised Units

- Ability to conduct destress welding

- High production, high quality welding on track or in a yard environment

HIGH PRODUCTION SLEEPER LAYING MACHINE

- 32T Cat Excavator

- Built in 2013

- Production rates of up to 3 kilometres per day

OLE PLATFORM-CONSIST

- Quantity - 2 - Zephir LOK 4.90 locomotive

- Quantity - 1 - Hercules

- Narrow gauge

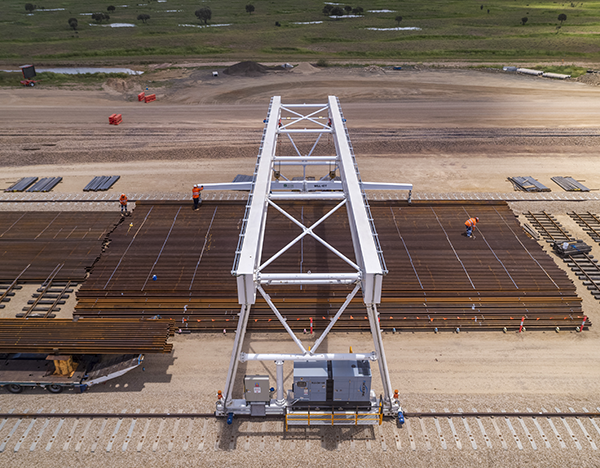

FLASH BUTT WELDING YARDS

AGITATOR

• Quantity – 1

• Narrow gauge

PLASSER SMD-80G TRACK LAYING AND REHABILITATION MACHINE

- Continuous motion track construction and rehabilitation machine accompanied by 2 gantry cranes and 26 sleeper wagons

- Gauge convertible between narrow and standard gauge

- Production rates of up to 300m per hour

RESURFACING PLANT

• Quantity – 4 Tampers and 4 Regulators

• Narrow and Standard gauge

• Mainline and Switch and Crossing tampers

HI-RAIL BUCKET TRUCK WITH PANTOGRAPH

• Quantity-1 HR Bucket Truck with Pantograph Attachment

• Tri-gauge

• OLE maintenance and construction

CONTINUOUS TRACK LIFTER x 2

• Quantity – 2

• Gauge Convertible

• High production rates whist achieving bulk track

lifts up to 150mm

TRIPP MACHINE

• Removal and Insertion of all types of sleepers

• Automated high production sleeper removal and

insertion

• Production rates of up to 900 sleepers per hour